13 best injection molding machines

Injection molding machines are industrial machines used in the manufacturing process of plastic products, components, and parts. They are not directly related to welding systems or equipment but fall under the category of machinery used in manufacturing and fabrication. Here's what you should know about injection molding machines:

Purpose: Injection molding machines are used to produce plastic parts by injecting molten plastic material into a mold cavity. Once the plastic cools and solidifies, the mold is opened, and the finished part is ejected.

Components: Injection molding machines consist of several key components, including:

- Hopper: This is where plastic pellets or resin are loaded into the machine.

- Barrel: The hopper feeds the plastic material into the barrel, where it is heated and melted.

- Screw or Plunger: The melted plastic is then injected into the mold cavity through a screw or plunger mechanism.

- Mold: The mold is a two-part tool that defines the shape and features of the final plastic part. It consists of a cavity and a core, and it can be custom-designed for specific products.

- Clamping Unit: The clamping unit holds the mold halves together during the injection process and ensures that the plastic material takes the desired shape.

- Cooling System: After injection, the plastic part needs to cool and solidify within the mold.

- Ejection System: This system pushes the finished part out of the mold cavity once it has cooled and solidified.

Injection Process: The injection molding process involves several steps:

- Plastic pellets are fed into the machine's hopper.

- The pellets are melted in the barrel through the application of heat and pressure.

- The molten plastic is injected into the mold cavity.

- The plastic cools and solidifies inside the mold.

- The mold opens, and the finished part is ejected.

Materials: Injection molding machines can work with a wide range of plastic materials, including thermoplastics and thermosetting polymers. The choice of material depends on the specific requirements of the product.

Applications: Injection molding is used to manufacture a vast array of products, including automotive parts, consumer goods, medical devices, electronic components, packaging, and more.It is a highly versatile and efficient manufacturing method.

Precision and Efficiency: Injection molding offers high precision and repeatability, making it ideal for producing complex parts with tight tolerances. It is also an efficient process in terms of material usage and production speed.

Variety of Machine Types: There are different types and sizes of injection molding machines, including hydraulic, electric, and hybrid machines, each with its advantages and applications.

Quality Control: Quality control is crucial in injection molding to ensure that each part meets the desired specifications. This includes monitoring variables like temperature, pressure, and injection speed.

Environmental Considerations: Injection molding can generate waste in the form of sprues (excess plastic material) and runners (channels for plastic flow). Efforts are made to recycle and minimize waste in the process.

In summary, injection molding machines are a critical part of the plastics manufacturing industry, enabling the production of a wide range of plastic products. They are characterized by their precision, versatility, and efficiency in producing high-quality plastic parts. While they are not directly related to welding equipment, they play a significant role in the world of manufacturing and fabrication.

Below you can find our editor's choice of the best injection molding machines on the marketProduct description

Alumilite Amazing Mold Rubber Kit, 0.77 oz.

- .77 oz kit

- High strength liquid silicone rubber

- Good for complex and multiple piece molds

- Flexible and Demolds in 2-4 hours

User questions & answers

| Question: | Can I use this to make molds of human body parts like fingers |

| Answer: | Because the cure time for silicone is long for body moldings, alginate is a much more common option. Although due to the high water content resisns will not cure in alginate. So unless you don't mind sitting with your finger in it for at least 2 hours without moving, would not recommend. |

| Question: | Can this be used to make a flat, thin mold of a textured design using polymer clay as the thing you are molding |

| Answer: | Yes but not too thin. Make sure the sides are high enough so when you pour your resin into the mold it doesn't run over the sides. Also, some resins might bend if they are too thin, so be careful unmolding. |

| Question: | How many good resin castings will I be able to make from one rubber mold |

| Answer: | I manage to make about 25-35 good castings from one rubber mold. After that, you can still cast, but there will be slight imperfections. |

| Question: | can you use this to make a mold of polymer clay statue |

| Answer: | I wouldn't recommend making a polymer clay statue, unless its something small. This product works best with resin casting. |

- Heavy-duty vacuum motor provides precise downward suction.

- Features a symmetrical heating system, ensuring uniform heat distribution.

- Adjustable, rust-resistant body accommodates various materials.

- Non-rotating sliding frame makes operation easy and stress-free.

- Compatible with all dental thermoplastics & Suitable for a wide range of clinical applications

User questions & answers

| Question: | what are the beads for that I see in the instruction video? Do they come with the machine |

| Answer: | Yes. They are ball bearing that can be used to increase suction in a smaller area if needed. |

| Question: | Can the Heating element be replaced |

| Answer: | I suggest it is best not to replace |

| Question: | Doses the vacuum forming machine come with the ball bearings? Are they necessary |

| Answer: | Yes, it comes with the ball bearings. I haven’t needed them for my particular molds. |

| Question: | What does this do |

| Answer: | Heats plastic sheets to a high temperature. The softened plastic sheet is then placed over an impression of someone’s teeth. This is called a bite guard. |

Product features

Ideal equipment for dental lab

Dental vacuum forming machine, suitable for a variety type of thermoplastic sheets, universal size 5” x 5” thermoplastic sheets could be applied in this vacuum forming machine. Ideal for making dental guard, orthodontic retainer, night guard and mouth guard.

Fast heating

Heating power up to 600 Watts, could soften thermoplastic in a few minutes. Horseshoe-shaped heating tube is evenly distributed in the center, with the honeycomb heat-dissipating net, the thermoplastic sheet can be uniformly heated to accelerate the softening speed and shorten the heating time.

Strong vacuum suction

Forming power up to 800 Watts, could mold thermoplastics in a few seconds. Heavy-duty vacuum motor provides precise downward suction, put the stainless steel beads on the forming platform could significantly increase suction, improve molding accuracy.

Easy and safe operation

Separate heating and forming switch easy to use, both with a red indicator attached to prevent misoperation.Follow the manual or operation demonstration video could be started your work quickly with this vacuum forming machine.

Rotatable heating plate

Top heating plate can be pushed to the left or right, convenient for fixing the thermoplastic sheet and placing the molding platform.

Firm sheets clamp

Sheet clamp with an active limit lock could hold the thermoplastic sheets securely.

Lengthen lift stick

Extended lift handle could safely raise and lower the sheet clamps for heating and forming.

Safe push rod

Special red push rod could safely push the top heating plate away to avoid high temperature burns.

Dental Vacuum Forming Machine

Product description

Facibom's trademark rights have been registered, and if any other merchants need to sell our products, please be sure to get authorization from us. Facibom will always be committed to providing customers with a quality shopping experience. The are used in many manufacturing processes such as the injection, extrusion and moulding processes

Or other specific applications such as tank heating and they are to be found in many industries such as the plastic processing industry, the car industry, chemical and food processing industries, etc

colour:yellow

Material:brass

size:Band size: 35mm x 35mm/1.4 inch x 1.4 inch(inner Dia.H)

Wire length: 350mm/13.7 inch

Package Contents:

1*Brass Band Heater

- Band Heaters, can be used in multiple aplications; easy installation, untie the screw with hex wrench

- energy saving, quick heating, for Plastic Injection Machine.

- For Injection Molding Machine, heating devices

- Volt&Watt: 110v&380w

- Band heaters are designed to heat up cylindrical parts by conduction.

Product description

400W Denture Injection System 110V Dental Flexible Denture Machine Dental laboratory Equipment

The 400W dental flexible denture machine, 110V dental laboratory equipment, is for making flexible removable partial dentures. Easy operation, long lifespan, low maintenance and high success rate, the denture injection system is very necessary for dentist.

Superiority

1. The denture manufactured by the invisible denture injection molding machine has almost no waste edge, and the grinding process can be completed in one time.

2. This machine is produced by international standards. Easy to operate, save time, high casting success rate, and ordinary tooth box can also be injection molded.

Component

This denture injection unit is composed of a heater and a hot press.

Heater: Temperature control, timer and electric system.

Hot Press: Frame, cylinder, heater, bracket and flask etc.

Working Principle

1. Heater - It heats the cartridge at the temperature of the 282-288ºC for about 7min30s-11min, making the flexible denture material melt in the cartridge.

2. Hot Press - It injects the molten material into flask which is prepared in advance.

NOTE

Please read the Product Manual carefully before operating the machine.

Specification

Product: Denture injection system

Voltage: AC 110V

Frequency: 60 Hz

Power: 400 W

Heating temperature: 282-288 ºC

Pressure time: 7min30s-11min

Intended use: Dentistry

Package size: 57x40x33 cm (22.44x15.75x12.99 inch)

Gross weight: 28.23 kg (62.24 lbs)

Package Content

1 x Heater

1 x Hot Press

1 x Set of Accessories

1 x Product Manual

- INTRODUCTION - This is 400W dental flexible denture machine, 110V dental laboratory equipment denture injection system. Heating temperature: 282-288 ºC. Pressure time: 7min30s-11min. Intended use: Dentistry

- ADVANTAGES - The denture injection machine is produced by international standards. Easy to operate, save time, high casting success rate, low maintenance, long lifespan and ordinary tooth box can also be injection molded

- COMPONENT - This denture injection unit is composed of a heater and a hot press. 1. Heater: Temperature control, timer and electric system. 2. Hot Press: Frame, cylinder, heater, bracket and flask etc

- WORKING PRINCIPLE - 1. Heater - It heats the cartridge at the temperature of the 282-288ºC for about 7min30s-11min, making the flexible denture material melt in the cartridge. 2. Hot Press - It injects the molten material into flask which is prepared in advance

- APPLICAITON - The denture injection system is designed for making flexible removable partial dentures, is necessary for dentist. The denture manufactured by the invisible denture injection molding machine has almost no waste edge, and the grinding process can be completed in one time

User questions & answers

| Question: | How do I turn the unit on |

| Answer: | Buen producto |

- Volt&Watt:110V&350W

- Band Size: 50mm x 50mm (Inner Dia. X Height);Wire Length: 255mm

- Material: Brass(Band)&Ceramic(Wire Connection)

- The ceramic connection is safe for wiring, and the brass band is anti-rust.

- Band heaters are designed to heat up cylindrical parts by conduction.

Product features

About Product

DERNORD Band Heater for Injection Molding Machine is made of brass and ceramic, and the brass band is anti-rust, the ceramic connection is safe for wiring. It is easy to install, just untie the screw with the hex wrench.

Product description

- Brass Band Heaters, can be used in multiple aplications; easy installation, untie the screw with hex wrench

- For Injection Molding Machine, heating devices

- Volt&Watt: 110v&380w

- Band size: 35mm x 35mm/1.4" x 1.4"(inner Dia.H); Wire length: 350mm/13.7"

- Package Included: 1 x brass band heater

User questions & answers

| Question: | what temperature does it go to |

| Answer: | The other guy is right, max temp is 300 degrees Celsius |

| Question: | How many amps would this draw? i want to run this using a dc - ac power inverter using a 12volt battery |

| Answer: | Two answers, actually. 380 watts / 120 volts = 3.167 amps. 380 watts / 12 volts = 31.67 amps but will draw more draw due to inefficiencies in the inverter. The 120 volt load can be handled by a thin 20 gauge wire but you'll need at least an 8 gauge wire to connect the inverter to the battery. Tesla was right, Edison was wrong. |

| Question: | how do you deliver power to this |

| Answer: | 110 elc power cord |

| Question: | I don’t understand the diamensions given - what in the internal diameter? 35mm |

| Answer: | heating coil slides over a 1 1/4" copper pipe |

- MAKE YOUR IDEAS REAL: The FormBox is your very own desktop production line. Whether you’re crafting by hand or partnering with your 3D printer, the FormBox fits perfectly into your workspace, so you can create a factory finish without the factory.

- POWERED BY ANY VACUUM: Just attach your usual vacuum cleaner, and you have industrial grade vacuum forming at home or in the office. Bring the power of the factory to you.

- PRECISION CONTROL: With simple, easy-to-use, smart settings, the FormBox will get you the exact finish you want. It picks up texture finer than a grain of sand, so you get all those little details you need to stand out from the crowd.

- SMALL PACKAGE, BIG POWER: The ceramic heater has a range of 160c to 340c, preparing your plastic to form. Carefully placed fans keep the FormBox running cool, meaning it works with a world of materials. A super fine mesh increases airflow to the 3D shape, placed on the bed, which is made from pressed steel for extra strength.

- NO MORE WAITING: Forget the lengthy back-and-forth design process and waiting for samples from factories – design, prototype and create your products yourself in a matter of minutes.

User questions & answers

| Question: | can i make a silicone mold for soy candle making |

| Answer: | No. This molds from plastic sheets formed over an object. You could make a mold from an object and then make a solid like plaster and then place the solid in a container of liquid silicone to dry. Then you would have a silicone mold. |

| Question: | i need to form a 175mm piece. i know you said it's 150mm suggested but wondering if it's possible |

| Answer: | The size of the FormBox bed is 200mm x 200mm, we usually say 150mm but you can stretch this a bit further to 180mm although it all depends on the dimension of your template i.e. width, length and height combined. If you have any more questions, you can email is directly via [email protected] |

| Question: | Can I use this to form silicon sheets |

| Answer: | You can use silicon sheets for creating casts, but Silicon is not compatible with Mayku for forming |

| Question: | what are the dimensions of the bed and how tall of a part can you form |

| Answer: | The size of the FormBox bed is 200mm x 200mm. The maximum width and length you are able to mold is 150mm x 150mm. To avoid tearing the plastic, we suggest not vacuum forming anything taller than it is wide. |

Product features

Hobbyists

With the FormBox, at-home makers can create simple forms from everyday items, like potatoes and plasticine. More serious hobbyists can make complex creations using other machines, including 3D printers, laser cutters, and CNC machines.

Educators

Schools have small budgets and are tight on space - the FormBox gives teachers a simple way to get kids excited about making, teaching STEM subjects in a fun and engaging way.

Create

3D print, sculpt or find your shape and place it on the FormBox bed.

Form

The FormBox forms a sheet of material around your shape - creating a mold in seconds.

Multiply

Fill your mold with dozens of materials from chocolate to resin, plaster and even concrete.

Finish

Take it out and bring your first collection of products to life! You can even use the FormBox to create custom packaging for your creation.

Product description

A small, hand-operated plastic injection molding machine for making prototypes and short-run production.micro manual Injection Molding Machine Maxi. temperature 490℃ Plunger diameter 20mm Maximum compressing stoke 135mm Heating cavity size 20*70mm Maximum shot volume 20cm3(20g) Mold max. size 120*120*80mm Machine weight 45kg Power supply 400w Voltage 220V/230V, 50/60HZ

- Date First Available :

- Manufacturer :

- ASIN :

- 360︒ SWIVEL: Our printing machine is 360 degree swivel, which helps to direct pressure straight down and apply pressure evenly, thus the quality of the finished transfers can be improved a lot, perfect for T-shirts, caps, ceramic plates, ceramic tiles, mugs, coasters, mouse pads, jigsaw puzzles, lettering, other misc. fabrics & materials.

- INNOVATIVE RAIL & NON-SKID HANDLE: Revolutionary alloy rail for easy transition among cup, hat and plate heat press cushion; anti-skid yellow handle made of rubber provides comfortable hand feeling.

- POWERFUL IN FUNCTION: 0- 500︒F temperature range, 0-999s timer control, and the temperature maintains constant once preset time is reached; dual LED displays keep tracking set temperature and time, defending your safety with smart design; Fahrenheit & Celsius convertible, accommodating different users’ needs.

- COMPREHENSIVE SAFETY: FCC certificated for unparalleled safety and quality; integrated intelligent audible alarm for safe operation.

- QUICK INSTALLATION & AFTER-SALE: Instruction enclosed for easy operation and installation, ready to use in 10 minutes; we offer good customer service to ensure you a good shopping experience. Don't hesitate to find us for repair or replace if the product is defective.

User questions & answers

| Question: | What’s the weight |

| Answer: | It's about 15 pounds. |

| Question: | Is there a teflon sheet on the heating element? it looks like there is and do i need to put one on shirt too? thanks |

| Answer: | There is a tier of Teflon cloth on the plank. You don't need to put one on a shirt. |

| Question: | What is the supply voltage |

| Answer: | Please check our listing, it's 110V |

| Question: | Can it print and also press |

| Answer: | Only press. |

Product features

Description:

This swing-away heat press boasts all of the must-have attachments. It can transfer colorful pictures and characters of sublimating and dissolved printing ink onto T-shirts, caps, ceramic plates, ceramic tiles, mugs, coasters, mouse pads, jigsaw puzzles, and lettering, etc. Create your own custom t-shirts, mouse pads, tote-bags, license plates, and many other unique & fun items with this magical t-shirt heat press machine.

Dual LED Display

- Keep tracking set temperature and time, defending your safety with smart design

- Fahrenheit & Celsius convertible

Spring Press Plate

- Special design of press plate make force well-distributed

- The spring press rod featuring convenience and easy operation

Teflon-coated Element

- Teflon coating to make it non-stick surface

- All the nuts, bolts, welding, etc. are correctly put in place

Anti-skid Yellow Handle

- Made Of Rubber

- Provide comfortable hand feeling

Product description

Product description:

De-ntal flexible denture machine is a 400W/110V De-ntal laboratory equipment for making flexible removable partial dentures.

The denture produced by the invisible denture injection molding machine has almost no waste edge, and the grinding process can be completed at one time.

The denture injection system is easy to operate, has a long service life, low maintenance cost, high success rate, and De-ntal laboratory equipment for denture injection system, which is very necessary for dentists.

This machine is produced according to international standards. The operation is simple, time-saving, the casting success rate is high, and the common tooth box can also be injection molded.

The denture injection unit consists of a heater and a hot press. Heaters: temperature control, timers and electrical systems. Hot presses: frames, cylinders, heaters, brackets and flasks.

Features:

Voltage: AC 110V/60Hz

Power: 400 W

Heating temperature: 282-288 ° C

Pressurization time: 7 minutes 30 seconds - 11 minutes

Packing size: 40*34*57cm

Gross weight: 30kg

The package includes:

1X heater

1X hot press

1X picking stick

1X small top bar

1X Big Top Bar

1X Type Box

1X box wrench

1X power cord

1Xproduct brochure

Steps:

1 The function of the heater is to heat the ink cartridge at a temperature of 282-288 ° C for about 7 minutes 30 seconds - 11 minutes to melt the flexible denture material in the ink cartridge. 2 The function of the hot press is to inject molten material into a previously prepared flask. 3 The heater will beep when it is heated.Note:Please read the product manual carefully before operating the machine

- BRIEF INTRODUCTION - Den-tal Denture Denture Machine is a 400W/110V den-tal denture laboratory equipment used to make flexible removable partial dentures.

- HIGH PERFORMANCE AND HIGH EFFICIENCY - The denture injection system is easy to operate, has a long service life, low maintenance cost, and high success rate. The Den-tal laboratory equipment of the denture injection system is essential for dentists.

- SIMPLE OPERATION - simple operation, time-saving and high casting success rate. Ordinary gear boxes can also be injection molded.

- PRODUCT COMPOSITION - Den-tal denture injection device consists of heater and hot press. Heater: temperature control, timer and electrical system. Hot press: frame, roller, heater, bracket and flask.

- WORKING PRINCIPLE - 1. The function of the heater is that it heats the cartridge at the temperature of the 282-288 ℃ for about 7min30s-11min, making the flexible denture material melt in the cartridge.2. The function of the hot press is that it injects the molten material into flask which is prepared in advance.3. The heater will make a beep sound when it finishes heating.NOTE:Please read the Product Manual carefully before operating the machine

Latest Reviews

View all

Large Margarita Glass

- Updated: 18.01.2023

- Read reviews

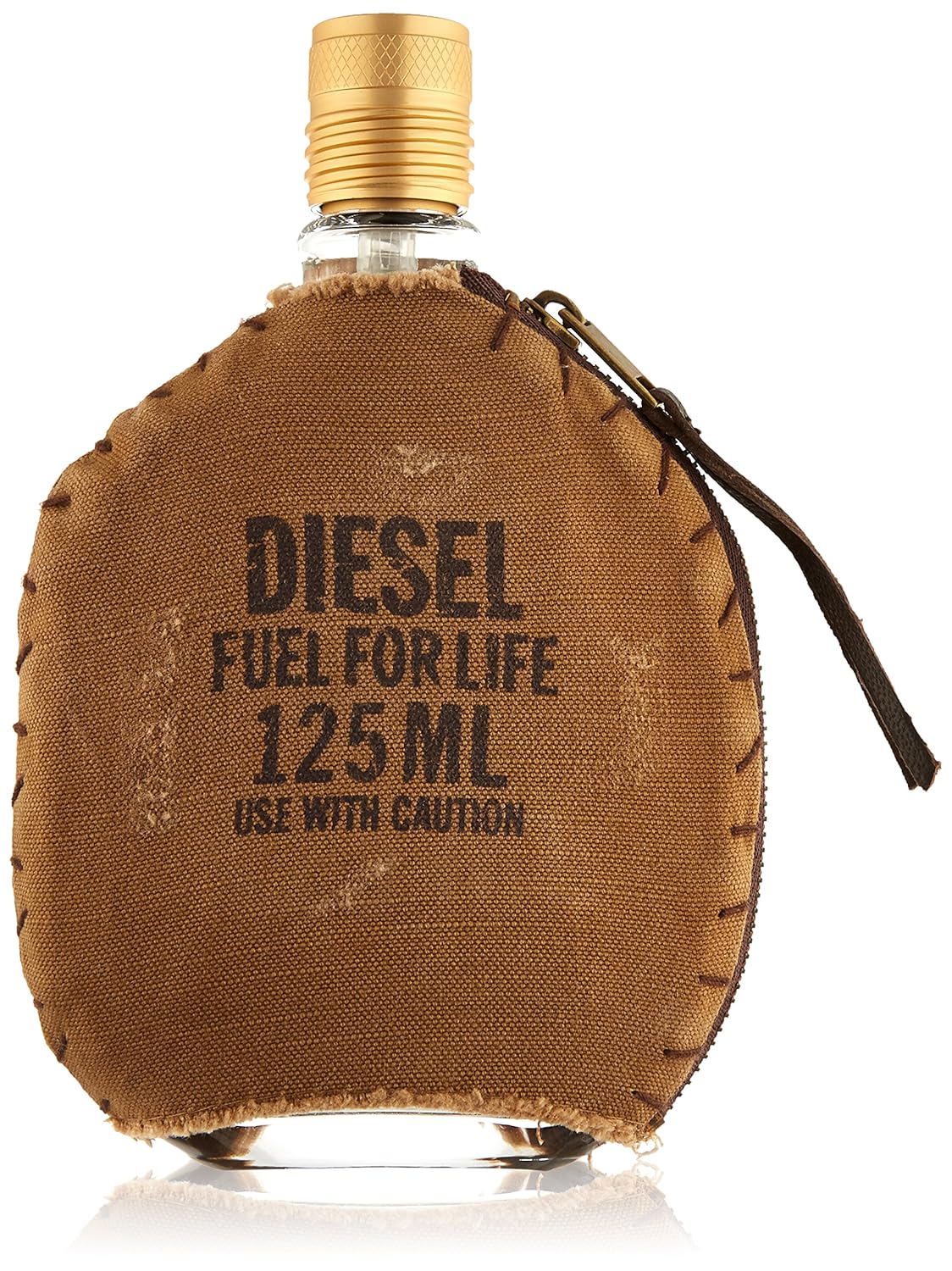

Diesel Perfumes For Men

- Updated: 20.06.2023

- Read reviews

Wireless Gaming Mouse

- Updated: 30.03.2023

- Read reviews

Skechers Lightweight Running Shoes

- Updated: 07.05.2023

- Read reviews

Rapid Digital Thermometers

- Updated: 09.05.2023

- Read reviews