14 best internal grooving inserts

Internal grooving inserts are cutting tools used in machining operations to create internal grooves or slots in workpieces. These inserts are a crucial component of modern machining processes, particularly in industries like manufacturing and metalworking. Here are some key points about internal grooving inserts:

Purpose: Internal grooving inserts are designed to cut grooves or slots on the inner surfaces of workpieces, such as bores, holes, or internal threads. They are used to create precision features within the workpiece.

Material: These inserts are typically made from hard and durable materials like carbide, cermet, or high-speed steel.The choice of material depends on the specific application and the type of material being machined.

Geometry: Internal grooving inserts come in various geometries, including square, round, and diamond-shaped inserts. The geometry of the insert determines the shape and dimensions of the groove it can produce.

Indexable Inserts: Internal grooving inserts are often designed to be indexable, meaning that they have multiple cutting edges. When one edge becomes dull or worn, the insert can be rotated or replaced with a fresh edge, extending the tool's lifespan and reducing downtime.

Compatibility: These inserts are designed to fit into specialized toolholders or boring bars. The choice of toolholder and insert must be compatible to ensure precise machining.

Applications: Internal grooving inserts are used in a wide range of applications, including the automotive industry, aerospace, and general machining. They are employed to create features like O-ring grooves, keyways, and internal threads.

Coolant Delivery: Some internal grooving inserts come with built-in features for efficient coolant delivery. Proper cooling and chip evacuation are essential for maintaining tool life and achieving high-quality results.

Chip Control: Effective chip control is crucial in internal grooving operations to prevent chip buildup and ensure a smooth cutting process. Chip breakers or chip-forming geometries on the inserts help manage chips.

Cutting Parameters: The choice of cutting parameters, such as cutting speed, feed rate, and depth of cut, plays a significant role in achieving optimal results with internal grooving inserts. Proper selection depends on the material being machined and the insert's geometry.

Tool Life: The tool life of internal grooving inserts can vary based on factors like material hardness, cutting conditions, and tool quality. Manufacturers often provide guidelines for the expected tool life under specific conditions.

In summary, internal grooving inserts are indispensable tools for machining internal features in workpieces. They come in various geometries, materials, and designs to suit different applications and machining requirements. Proper selection, maintenance, and cutting parameter optimization are essential for achieving high-quality results and extended tool life.

Below you can find our editor's choice of the best internal grooving inserts on the market- Size:Turning Inserts MGMN200 6mm x 3mm x 2mm

- Material: made of solid carbide with multilayer coated, offer long tool life and faster cutting speed, low friction coefficient, good wear resistance

- Designed for Steel, cast iron and non-ferrous materials

- Fit for MGEHR / MGIVR grooving cut-off tool.

- 10pcs With a plastic box for convenient storage

Product features

Size:

6mm x 3mm x 2mm

Feature:

Designed for Steel, cast iron and non-ferrous materials

Used for turning and finishing on a wide range of materials

Fit for: MGEHR/MGIVR Grooving Cut-Off Tool

Noite:Solid carbide Insertsare more brittle than other substrates, and must be used with rigid tool holding systems

Product description

Buy direct from THINBIT. GROOVE 'N TURN LR3406 3/4" Diameter, Round internal toolholder. Reversible for Left or Right hand orientation. Use with grooving, turning, chamfering and threading inserts. Kaiser Tool Company, Inc. makes all products in Fort Wayne, Indiana and has over 50 years producing THINBIT products. Our principles are Quality Products, Fast Delivery and Superior Customer Service. Please Note: Final shipping costs will be calculated at checkout based on value of all THINBIT items ordered. THINBIT and GROOVE 'N TURN are registered trademarks exclusively licensed to Kaiser Tool Company, Inc. in the U.S. and/or other countries.

- See Downloads section below item photos for detailed product information, technical information and compatible inserts.

- Designed for CNC, Swiss and conventional machines. Toolholder includes: C Clamp, S3808 Screw, W1005 Wrench and P0305 Pin.

- This toolholder is compatible with grooving, turning, chamfering and threading inserts. Use inserts beginning with 'L'.

- When used for cutting undercuts along an internal shoulder, select: Left hand inserts for M03 rotation or Right hand inserts for M04 rotation.

- U.S. Patent 6,688,816 and 6,824,333.

Product description

Kyocera Precision Tools is a leading manufacturer of indexable End Mills, Face Mills, Drills, Grooving, and Turning tools used around the world in diverse markets such as the automotive, medical, oil, and aerospace industries.

Product description

HHIP TIALN coated internal threading and grooving carbide insert with right hand cutting direction. UN-60 degree full profile threading insert. Tolerance class is 2A/2B. Specification : Insert#: 11NR-18UN; I. C: 1/4; Screw Pitch TPI : 18; Length: 0. 63"; X: 0. 031"; Y: 0. 039"; Thick: 0. 126".

- UN-60 degree full profile threading insert

- Right hand cutting direction

- Tolerance class is 2A/2B

- Screw pitch is 18 TPI

- Thickness is . 126"

Product description

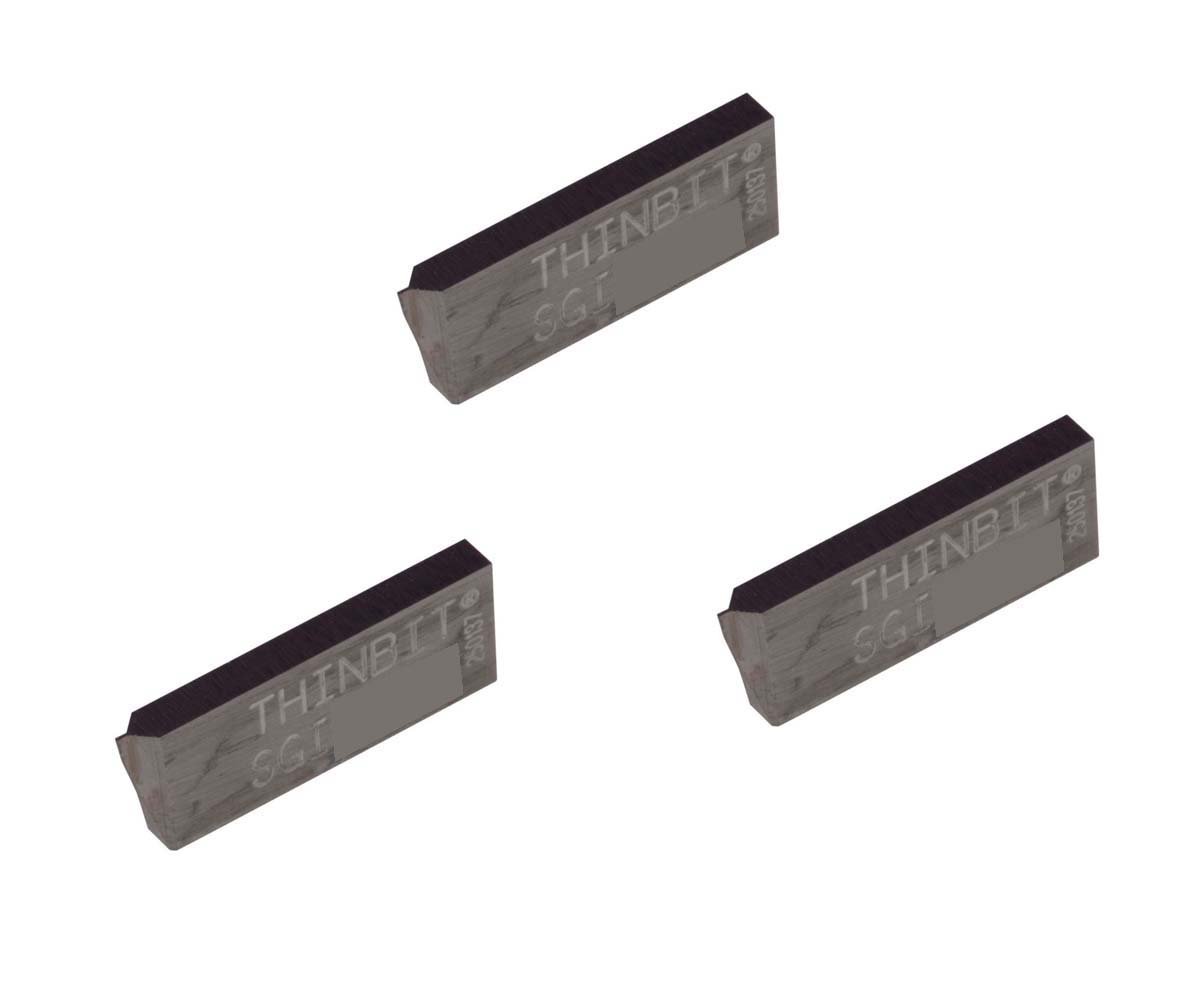

Buy direct from THINBIT. GROOVE 'N TURN 3 Pack LGT063D5L 'L' Series, Uncoated carbide, Grooving insert. .063" wide, Sharp Corner, 0 radius, .158" depth of cut. DURA-MAX 5000 carbide is a hard, abrasion resistant, sub-micron grain carbide with excellent edge and corner retention. This grade is recommended for cutting abrasive materials, non-ferrous alloys, aluminium, plastic and applications without an interrupted cut. Kaiser Tool Company, Inc. makes all products in Fort Wayne, Indiana and has over 50 years producing THINBIT products. Our principles are Quality Products, Fast Delivery and Superior Customer Service. Please Note: Final shipping costs will be calculated at checkout based on value of all THINBIT items ordered. THINBIT, GROOVE 'N TURN and DURA-MAX are registered trademarks exclusively licensed to Kaiser Tool Company, Inc. in the U.S. and/or other countries.

- See Downloads section below item photos for detailed product information, technical information and compatible toolholders.

- Cuts up to .158" deep. Can be used for parting stock up to .316". Cuts flush to collet face or shoulder of larger diameter.

- Designed for grooving and multi-directional turning. Use to generate grooves, arcs and angles.

- Uncoated DURA-MAX 5000 carbide grooving insert for non-ferrous alloys, aluminium and plastic without interrupted cuts.

- Use with Large series toolholders. Use LH straight or RH 90 degree.

- Insert Style: GTN-3

- Insert Grade: C5

- Insert Width: 0.12"

- Cutting Direction: Neutral

- Coating: Tin

Product features

Shars Tool Cut-Off & Grooving Insert

- APPLICATION: Grooving

- INSERT STYLE: GTN

- INSERT GRADE: C5

- MATERIAL: Carbide

- COATING: Tin

- CUTTING DIRECTION: Neutral

Features

- 0 degree lead angle

- High reliability

- High rigidity

- Increased stability

- Superior straightness of cut

- For cut-off and grooving, Single-sided notation, TiN coated for extra strength at higher speeds.

- Grade C-6 is a general purpose grade for cutting all steel and stainless steels.

Product description

Parameter:

- B:2

- R:0.2

- L:16

- D:1.2

- S:3.5

- Material: Carbide

- Machining Material: Steel

- Chip Breaker: MD

- Machining Process: for Parting and Grooving

- *PVD AI2O3 Coating,compare with PVD coating,the inserts's wear resistance and heat resistance improved.

- *Suitable for machining steel and cast iron, processing soft stainless steel and aluminum line.

- Modle:MGMN200-M

- Material:Carbide

- Coating:PVD Coated

- Machining Parts Material: Steel, Fit for MGEHR / MGIVR grooving cut-off tool

- Quantity:10pcs/box

Product description

Buy direct from THINBIT. GROOVE 'N TURN 3 Pack LGT100D2RE 'L' Series, TiAlN Coated carbide, Grooving insert. .100" wide, Sharp Corner, 0 radius, .250" depth of cut. DURA-MAX 2000 is a versatile and tough sub-micron grain carbide. Because of its high transverse rupture strength and fine grain structure, DURA-MAX 2000 performs well with interrupted cuts. TiAlN is a high performance PVD coating which excels in cutting abrasive or difficult-to-machine materials such as titanium, inconel, waspaloy, hastelloy, high nickel alloys and harder varieties of stainless steel. TiAlN performs well in high temperatures, interrupted cuts and dry machining. Kaiser Tool Company, Inc. makes all products in Fort Wayne, Indiana and has over 50 years producing THINBIT products. Our principles are Quality Products, Fast Delivery and Superior Customer Service. Please Note: Final shipping costs will be calculated at checkout based on value of all THINBIT items ordered. THINBIT, GROOVE 'N TURN and DURA-MAX are registered trademarks exclusively licensed to Kaiser Tool Company, Inc. in the U.S. and/or other countries.

- See Downloads section below item photos for detailed product information, technical information and compatible toolholders.

- Cuts up to .250" deep. Can be used for parting stock up to .500". Cuts flush to collet face or shoulder of larger diameter.

- Designed for grooving and multi-directional turning. Use to generate grooves, arcs and angles.

- TiAlN Coated DURA-MAX 2000 carbide grooving insert for steel, titanium, nickel alloys and stainless steel with interrupted cuts.

- Use with Large series toolholders. Use RH straight or LH 90 degree.

- CTN-5(QC1405) Turning insert, Thickness:5.1mm(2")

- Material: made of solid carbide with multilayer coated, offer long tool life and faster cutting speed, low friction coefficient, good wear resistance

- For cut-off and grooving

- For cutting all steel and stainless steels and non-ferrous materials

- 5pcs With a plastic box for convenient storage

Product features

Feature:

Designed for Stainless Steel, Steel, cast iron and non-ferrous materials

Fit for:Grooving Cut-Off Tool

Noite:Solid carbide Insertsare more brittle than other substrates, and must be used with rigid tool holding systems

Product description

Buy direct from THINBIT. LITTLEBIT 3 Pack SGI020D5 'S' Series, Uncoated carbide, Grooving insert. .020" wide, Sharp Corner, 0 radius. .060" depth of cut. DURA-MAX 5000 carbide is a hard, abrasion resistant, sub-micron grain carbide with excellent edge and corner retention. This grade is recommended for cutting abrasive materials, non-ferrous alloys, aluminium, plastic and applications without an interrupted cut. Kaiser Tool Company, Inc. makes all products in Fort Wayne, Indiana and has over 50 years producing THINBIT products. Our principles are Quality Products, Fast Delivery and Superior Customer Service. Please Note: Final shipping costs will be calculated at checkout based on value of all THINBIT items ordered. THINBIT, LITTLEBIT and DURA-MAX are registered trademarks exclusively licensed to Kaiser Tool Company, Inc. in the U.S. and/or other countries.

- See Downloads section below item photos for detailed product information, technical information and compatible toolholders.

- Perfect for o-rings, snap rings and piston rings. Cuts within 1/16" of collet face or shoulder of larger diameter.

- Designed for plunge grooving up to .060" deep. Can also be used for parting stock up to .120".

- Uncoated DURA-MAX 5000 carbide grooving insert for non-ferrous alloys, aluminium and plastic without interrupted cuts.

- Use with Small series toolholders.

Product description

Only Special Blades And Processing Corresponding Materials Can Highlight The Value Of The Blades, And Can Produce The Quality You Want. For Processing Steel, Choose This Blade! High Finish, Imported Raw Materials, Sharp Edges, Smooth Chip Removal, Excellent Wear Resistance, Good Deformation Resistance, Fast Cutting Under The Same Conditions, No Sticking To The Knife, High Efficiency, And The Finish You Want.

- It Is Processed By Imported Technology And Has The Advantages Of High Hardness, Strong Wear Resistance, High Smoothness, Not Easy To Stick To The Knife, And Smooth Chip Removal.

- Different R Angles Can Meet Your Needs For Fine Turning Or Rough Turning, Reduce Cutting Resistance, And Achieve Sharp Cutting.

- The Turning Is Light And Fast, And The Advanced Coating Process Is Sprayed By The 1000-Degree Stress Accumulation Method, The Coating Is Thicker, And The Cutting Edge Is Passivated, Strong And Durable.

- The Unique Groove Design Can Make Chip Removal Faster And Smoother, So As To Ensure That The Excrement Will Not Scratch The Surface Of The Product!

- The Blade Is Both Sharp And Thick, So That It Can Realize The Ideal Processing That Is Fast And Not Easy To Stick To The Knife, High Smoothness And Not Easy To Break.

Product description

Buy direct from THINBIT. GROOVE 'N TURN LGOR142D5CR010, 'L' Series, Uncoated carbide Static O-Ring grooving insert for .200" depth of cut. DURA-MAX 5000 carbide is a hard, abrasion resistant, sub-micron grain carbide with excellent edge and corner retention. This grade is recommended for cutting abrasive materials, non-ferrous alloys, aluminium, plastic and applications without an interrupted cut. Kaiser Tool Company, Inc. makes all products in Fort Wayne, Indiana and has over 50 years producing THINBIT products. Our principles are Quality Products, Fast Delivery and Superior Customer Service. Please Note: Final shipping costs will be calculated at checkout based on value of all THINBIT items ordered. THINBIT, GROOVE 'N TURN and DURA-MAX are registered trademarks exclusively licensed to Kaiser Tool Company, Inc. in the U.S. and/or other countries.

- See Downloads section below item photos for detailed product information, technical information and compatible toolholders.

- Uncoated DURA-MAX 5000 carbide Static O-Ring grooving insert for non-ferrous alloys, aluminium, plastic without interrupted cuts.

- Use with Large Series toolholders.

- .142" tip width with .010" corner radii. 7 degree included angle. .200" depth of cut. Internal grooving with 1.250" minimum bore.

- U.S. Patent 6,688,816 and 6,824,333.

- GBJ-1 10pcs SP200 NC3020 GTN-2 Grooving Cut-Off Carbide Inserts

User questions & answers

| Question: | What are the dimensions of this item? width of cut |

| Answer: | .750 approximately with you keeping tool lubricated often with slow feed .cleaning out the groove your making with it. |

Product features

ASIN: B08D6M9PSG

Our aim is to make you enjoy the lowest market p rice, best quality by the market!

ASIN: B06XTX6J99

We have our own production equipment Custom production accepted Quality assuranc e Lowest p rice!

ASIN: B08CN9XD91

CNMM1906024

The quality better than the famous brands in Japan and Korea

ASIN: B08DFSYBWD

All kinds of tool holders, Factory direct sales of goods are definitely value for money!

Product description

Kyocera Precision Tools is a leading manufacturer of indexable End Mills, Face Mills, Drills, Grooving, and Turning tools used around the world in diverse markets such as the automotive, medical, oil, and aerospace industries.

Latest Reviews

View all

Mega Men

- Updated: 24.07.2023

- Read reviews

Steam Vac For Tile

- Updated: 12.03.2023

- Read reviews

Underarm Thermometers

- Updated: 01.05.2023

- Read reviews

Books For Baby Girls

- Updated: 13.05.2023

- Read reviews

Natural Vegetable Vitamins

- Updated: 02.05.2023

- Read reviews